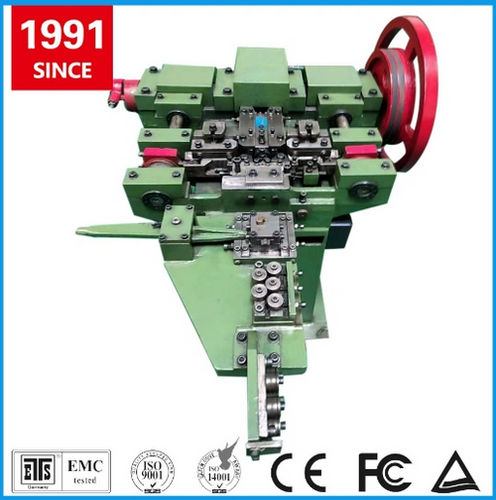

Customized High Speed Headless Thread Rolling Machine

Customized High Speed Headless Thread Rolling Machine Specification

- Production Capacity

- 180-250 pieces/min

- Noise Level

- Under 80 dB

- Frequency

- 50 Hz

- Connectivity Options

- Ethernet, USB, Remote Monitoring

- Accuracy

- 0.01 mm

- Operating Temperature

- 5C ~ 45C

- Lubricating System

- Centralized Automatic Lubrication

- Frame Type

- Heavy-Duty Welded Steel

- Features

- Customizable Thread Profiles, High Precision, Low Maintenance

- Motor Power

- 7.5 kW

- Machine Type

- High Speed Thread Rolling

- Power Rating

- 7.5 kW

- Voltage

- 415V

- Cooling System

- Integrated Water Cooling

- Drive

- Direct Drive

- Control System

- PLC Control Panel

- Model No

- CHR-250A

- Product Type

- Headless Thread Rolling Machine

- Technology

- Cold Forming

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 7.5 kW

- Pressure

- Adjustable up to 18 Tons

- Surface Treatment

- Anti-corrosive Paint Finish

- Dimension (L*W*H)

- 2300 x 1200 x 1600 mm

- Weight (kg)

- 2250 kg

- Color

- Industrial Green

- Usage & Applications

- Screw and bolt manufacturing

- Max Thread Length

- 80 mm

- Operator Interface

- Touchscreen HMI

- Roller Speed Adjustment

- Variable

- Packing Type

- Wooden Crate

- Maintenance Cycle

- Every 750 operating hours

- Thread Diameter Range

- 2 mm to 10 mm

- Warranty Extension

- Available upon request

- Safety Features

- Emergency Stop, Protective Guards

- Ambient Humidity Tolerance

- up to 80%

- Roller Material

- High-grade Tool Steel

- Spindle Type

- Precision Hardened

- Power Consumption

- 7.5 kW/hr

- Export Markets

- Global

Customized High Speed Headless Thread Rolling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Main Export Market(s)

- Asia, South America, Middle East

- Main Domestic Market

- All India

About Customized High Speed Headless Thread Rolling Machine

Dongguan Arida Machinery Equipment Co., LTD, a company specializing in manufacturing fastener machines, is located in the hinterland of the Pearl River Delta, Zhaoqing Dawang Industrial Park, a national high-tech development zone, was founded in 1991. Which covers an area of 150 acres/ 100000 square meters and employs over 400.

Model NO.

thread rolling machine

Surface Treatment

Electroplating

Forging Tolerance

+/-0.1mm

Standard

JIS

Certification

CE, RoHS, ISO 9001:2000, ISO 9001:2008

Transport Package

Standard Export Package

Trademark

ARIDA

Origin

China

HS Code

8462119000

Production Capacity

200set/Month

Precision Engineering Meets High-Speed Production

Designed for manufacturing screws and bolts, the CHR-250A ensures accuracy with each pass. Its precision hardened spindle and high-grade tool steel rollers guarantee reliable threading while facilitating quick changeovers for custom thread profiles. Automatic PLC-controlled functions maximize output while maintaining consistency across large-scale operations.

Intuitive Operation and Enhanced Safety Features

A touchscreen HMI allows simple control, while protective guards and emergency stop features elevate workplace safety. The heavy-duty welded steel frame endures rigorous use, and centralized lubrication keeps maintenance minimal. Operators benefit from variable speed settings and integrated cooling, ensuring safe and comfortable working conditions.

Global Connectivity and Customization Options

With Ethernet and USB connectivity, remote monitoring is straightforward. Adjustable threading pressure up to 18 tons permits flexible operation, and anti-corrosive paint finish ensures longevity. Available warranty extension and packing in durable wooden crates provide security for international distributors, suppliers, and manufacturers.

FAQ's of Customized High Speed Headless Thread Rolling Machine:

Q: How does the CHR-250A thread rolling machine operate for screw and bolt production?

A: The CHR-250A uses cold forming technology, applying up to 18 tons of adjustable pressure to shape threads with high precision. Automatic operation, PLC-controlled settings, and variable roller speeds ensure every component meets strict standards while optimizing throughput.Q: What are the key benefits of the integrated touchscreen HMI and remote monitoring?

A: The touchscreen HMI streamlines operation, configuring machine settings with ease. Remote monitoring via Ethernet or USB enables users to track performance, troubleshoot, and conduct diagnostics, reducing downtime and increasing efficiency.Q: When should maintenance be performed on this thread rolling machine?

A: A maintenance cycle is recommended every 750 operating hours. This includes checking the centralized lubrication system, cooling system, and inspecting safety features to maintain optimal performance and machine longevity.Q: Where is the CHR-250A suitable for use and distribution?

A: This machine supports global export and distribution. Its robust frame, wooden crate packaging, and anti-corrosive paint make it ideal for diverse manufacturing environments and international logistics requirements.Q: What processes or applications is this machine best suited for?

A: It is primarily designed for high-volume manufacturing of screws and bolts, accommodating customizable thread profiles. The machine delivers consistent, high-accuracy threads at high speeds for industrial hardware production.Q: How does the machine maintain user safety during operation?

A: Operator safety is elevated with features such as emergency stop, protective guards, and low noise levels (under 80 dB). These, along with temperature and humidity tolerance, create a safe and ergonomic workspace.Q: What are the advantages of using high-grade tool steel rollers and an anti-corrosive frame?

A: High-grade tool steel rollers offer durability, precision, and resistance to wear, while the anti-corrosive paint and heavy-duty steel frame ensure the machine withstands demanding conditions, providing long service life and minimal upkeep.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cold Heading Forming Machines Category

Customized High Speed 713-Nail Making Machine

Price 25592 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Powder Coated & Painted

Operating Type : Automatic

Color : Blue / Silver

Usage & Applications : Nail Manufacturing for construction, hardware, and industrial applications

China Customized High Speed Straightening Cutting Ring Rolling Machine

Price 19995 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Anticorrosive Painted

Operating Type : Automatic

Color : Customized (Standard: BlueGrey)

Usage & Applications : Wire straightening, cutting, and ring rolling for construction and industrial use

Multi Station 3 Mould Die 6 Forging Bolt Making Machine

Price 12365 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Painted

Operating Type : Automatic

Color : Blue

Usage & Applications : Bolt manufacturing, fastener industry

Chinese Hex Socket Head Cap Screw Threading Rolling Machine

Price 2150 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Painted